Imagine you're running a mid-sized manufacturing company, and you've decided it's finally time to introduce a Product Lifecycle Management (PLM) system.

You're looking forward to having all your product data in one place, smoother processes, and operations that just work better.

You can already see your engineering and supply chain teams collaborating more easily, fewer mistakes popping up in production, and products getting out to customers faster.

You're expecting lower costs, better quality products, and smarter decisions based on clear data—ultimately leading to happier customers and higher profits.

The challenge: Finding the right PLM software

Now, an important question comes up: What are you going to use as your PLM software? Naturally, Excel seems a good choice. After all, it's the second-best tool for everything. But then you realize how separated everything will be.

You'll have to send everything by email. There won't be any connection to business processes, engineering, inventory, or your customers. Not to mention the suppliers and subcontractors. In the end, there's just complete, hopeless, and utter disconnection.

But wait, there's more:

- Slow and painful processes, because managing data in Excel is inherently slow, inefficient, and prone to errors, causing workflow delays.

- Data silos with critical design and production information scattered across multiple documents, making collaboration difficult.

- Communication challenges, with disconnected workflows and tools, making team alignment particularly difficult.

- Limitations in data sharing and updates when you only rely on Excel for managing Bills of Materials (BOMs).

- Inventory errors and increased costs that inefficient data management can lead to.

- Challenges in managing revisions and keeping everyone up to date with the latest version.

As you shake the blank stare from your eyes and wipe the cold sweat off your face, you tell yourself there's gotta be a better option. And you're right, there is. It's called OpenBOM.

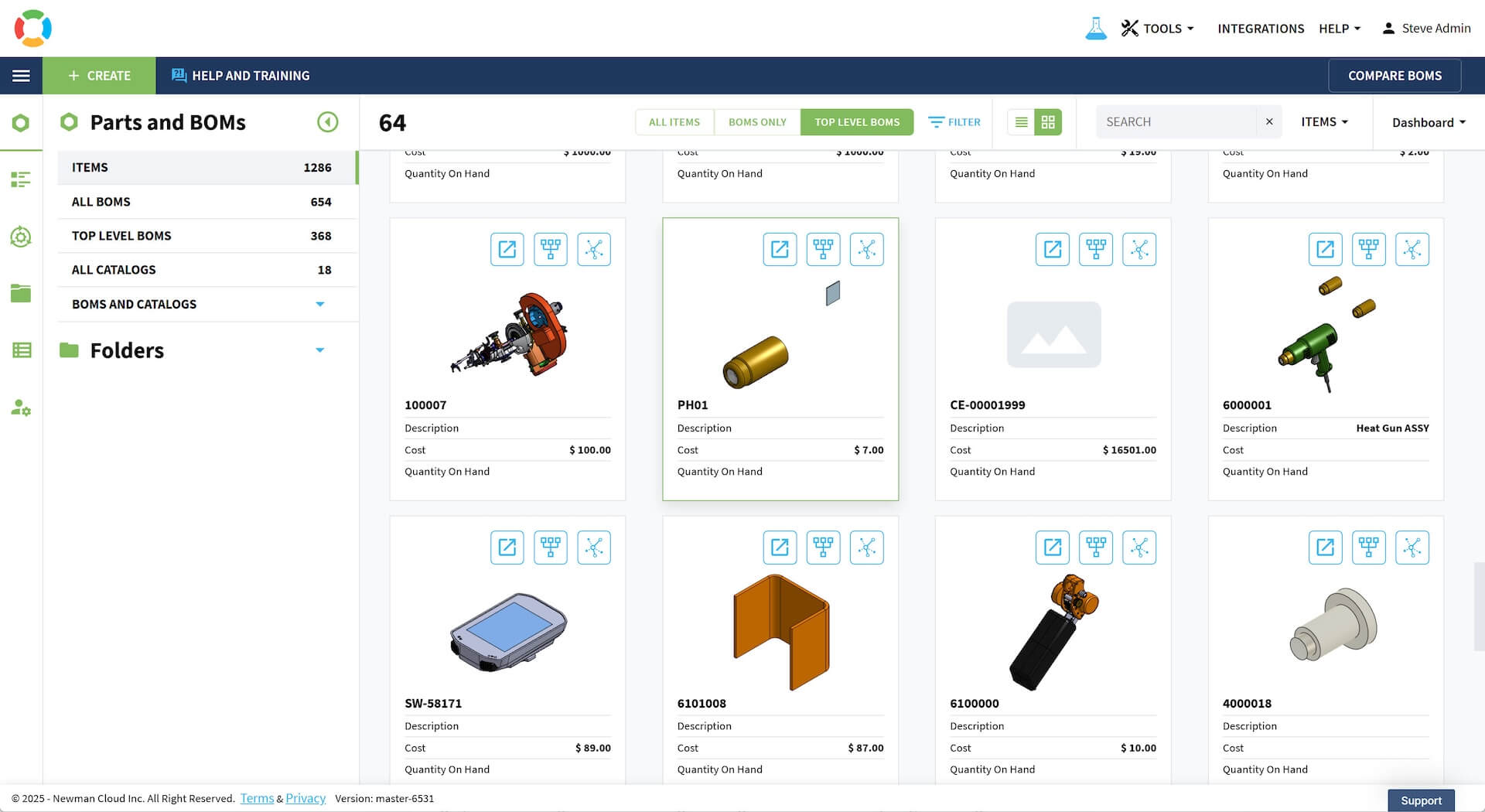

OpenBOM brings all your data into one place, for everyone

OpenBOM is a collaborative workspace platform that can run your PLM with ease:

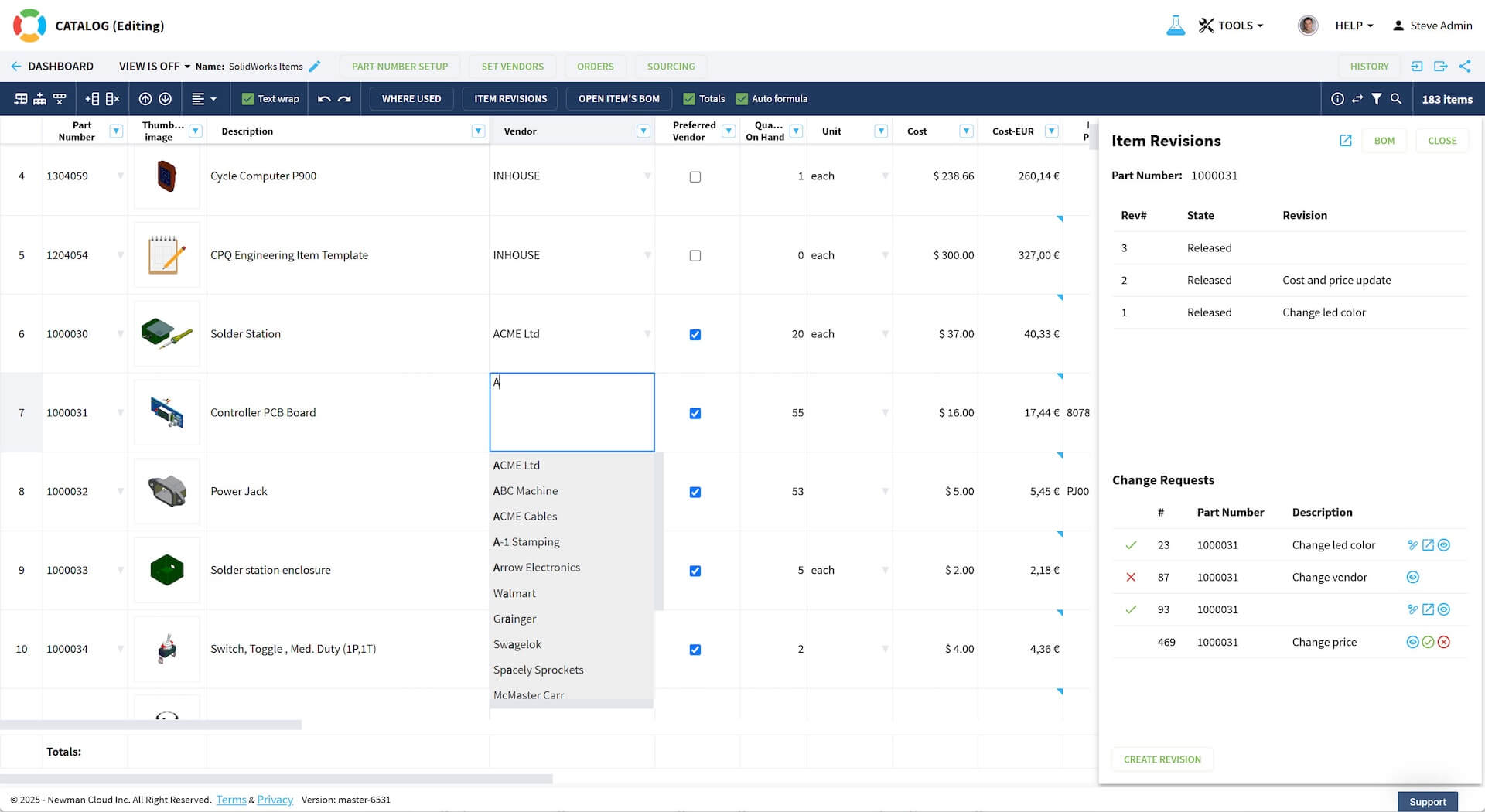

- Works like Google Sheets by connecting complex data to the grid and allowing multiple people to make simultaneous changes.

- Brings product design data from engineering to the entire company, creating smoother workflows and communication.

- Organizes all product-related data in one place, preventing data silos and giving teams instant access to accurate, real-time information.

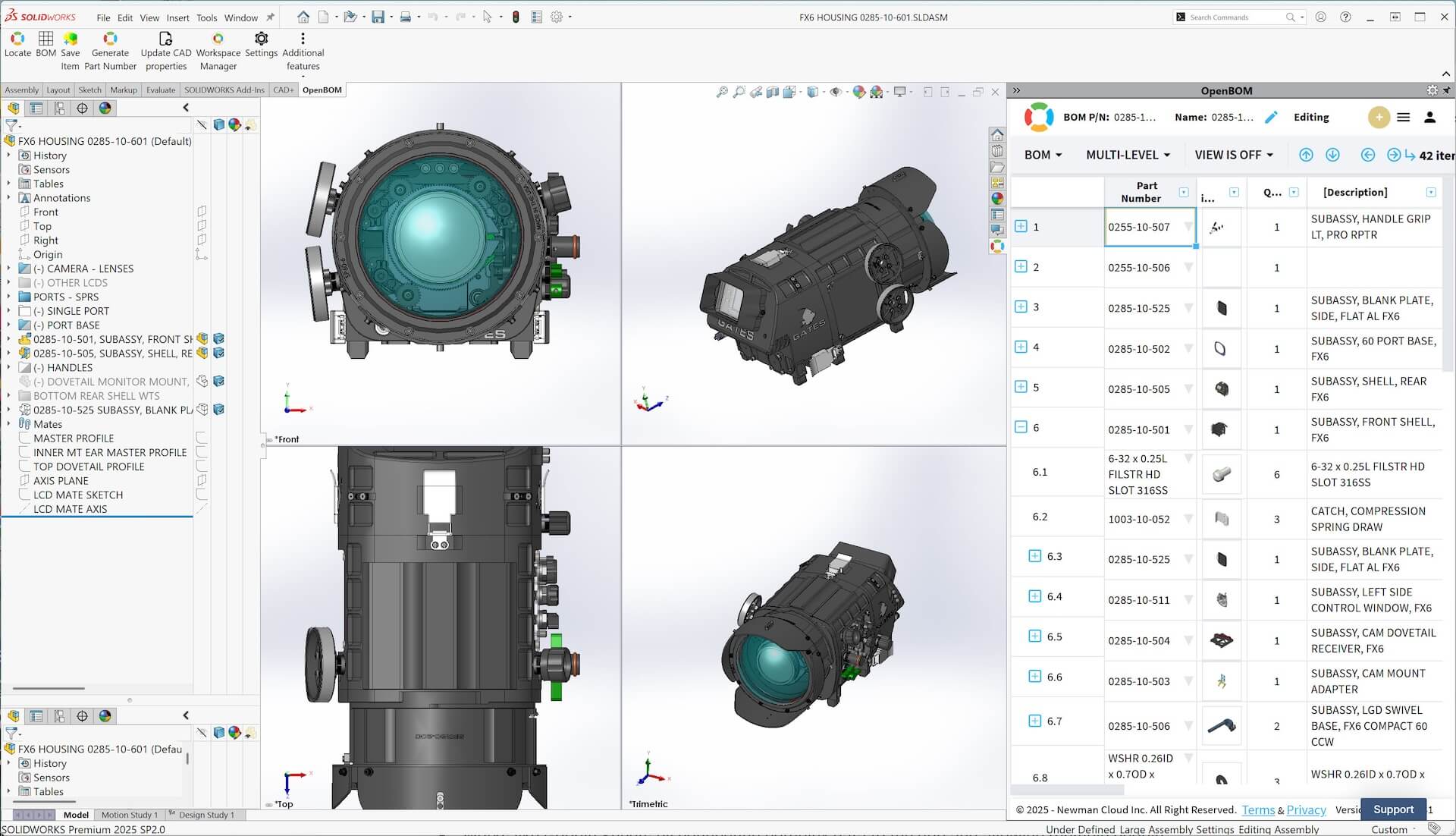

- Integrates with popular tools like CAD, ERP, and CRM, allowing easier data sharing across departments and external partners.

- Eliminates manual data transfer between systems and reduces errors and delays.

- Helps prevent costly mistakes that can arise from outdated or inaccurate information, such as building the wrong parts and having to scrap them.

- Speeds up revisions and prevents miscalculating costs due to unawareness of price changes.

- Offers traceability and compliance features to companies in regulated industries, like medical and aviation.

- Frees up teams to focus on creativity and new product development by reducing administrative burdens.

Hours and money saved across the board

The bottom line value for OpenBOM's customers is that the platform creates huge time and cost savings. Some things they've said include:

- It's a game changer because it lets them have live, linked BOMs to CAD files.

- It gives them confidence in delivering reliable BOMs to their suppliers and manufacturers.

- It streamlines and shortens production time from initial concept to finished drawings.

- With software add-ins, like Solidworks for example, they can work in the software and not have to switch back and forth to Excel to extract data.

- It helps them be as lean as possible and order only what is needed, massively reducing stock quantities.

And now for the really impressive results you can put a number to:

- OpenBOM saves two hours of engineering time daily.

- It reduces data extraction from CAD from 10 hours to one click.

- Reusing an existing BOM to create a new one has gone from one hour to 5 minutes.

- Generating an accurate BOM has gone from a day to a few minutes.

Let's not forget about Excel, though. Such a popular tool begs to be implemented somehow into a system like OpenBOM. As a customer-centric company, they understand the value in giving their customers a familiar, Excel-like experience.

And that's where Handsontable data grid comes in.

How Handsontable helps make OpenBOM so efficient

First off, engineers love Excel. So how do you talk to them in a language they understand? You start with a grid that looks like Excel. If you try to do it some other way, they're going back to Excel.

Thanks to Handsontable, OpenBOM gives their customers a familiar UI that makes the software easier to use. Since it looks like Excel, they slide right into it. This makes onboarding smoother and boosts user satisfaction.

OpenBOM sees Handsontable data grid as the cast iron block in the motor that drives their platform. It's an out-of-the-box solution that gives them the spreadsheet features they need, like sorting and filtering, to help create a powerful and efficient piece of software.

By integrating Handsontable with their own backend functions, OpenBOM can customize the platform's functionality to fit the specific needs of their users, creating great value for themselves and their customers.

Handsontable brings familiarity and value to our customers in that OpenBOM looks and feels like a traditional spreadsheet, but with powerful engineering functions provided by OpenBOM.

When it comes to the business value of implementing Handsontable, it's ultimately code that OpenBOM doesn't have to write and maintain. Moreover, since the JavaScript data grid follows modern coding practices, OpenBOM's developers can easily integrate it into their existing codebase.

All of this means Handsontable helps OpenBOM save development time and other company resources because it's one less developer they have to hire. And since developers can focus more on OpenBOM's core features and functionalities, Handsontable helps pave the way for a faster go-to-market.

Handsontable is one less component we must develop and maintain in our code. I can put that developer to work on OpenBOM core features that benefit our customers.